NPB Technology in MSW

There are different types of mechanical Drying technology available, but all are highly advanced & requires high capital cost. Majority of Mechanical drying technology requires excessive external energy, huge space, pollution control equipments, water treatment facility - for drying of MSW.

Municipal Solid Waste’s (MSW)

EFFECTIVE, EFFICIENT & ECONOMIC (EEE) Management is the critical issue in all country across world

There are different types of mechanical Drying technology available, but all are highly advanced & requires high capital cost. Majority of Mechanical drying technology requires excessive external energy, huge space, pollution control equipments, water treatment facility - for drying of MSW. All this equipment adds an additional process, that has got its own problems & limitations, which makes the drying of MSW as major obstacle in further application & processing integration.

IEC has came up with its unique technology of BIOdrying for EEE management of MSW.

Renerzyme

Microbial Cultures of GRAS microbe contains organic acids, metabolites, organic salts etc. It can dominate local micro flora & fauna in no time. At the same time, it works to activate local dormant beneficial microbial species in the eco-system. NPB GRAS microbe & local beneficial microbe work in tandem to create synergies to take charge of the eco-system & generate temperature as high as 80° cent. This unique action is known as ‘Bio-Drying’.

During multiple cycles of biodegradation, a widely diverse population of micro organisms catabolises substrates through complex biochemical reactions to satisfy metabolic and growth needs, gradually leading to mineralisation of organic substances.

In case of MSW management, BIOdrying technology can bring in following changes in eco-friendly manner

- Odour control in few hours from applicationc

- No segregation of Non-biodegradable (Plastics, Metal, Glass, Clothes, Leather etc). Non-biodegradables are removed during sieving operation, when its hygienic

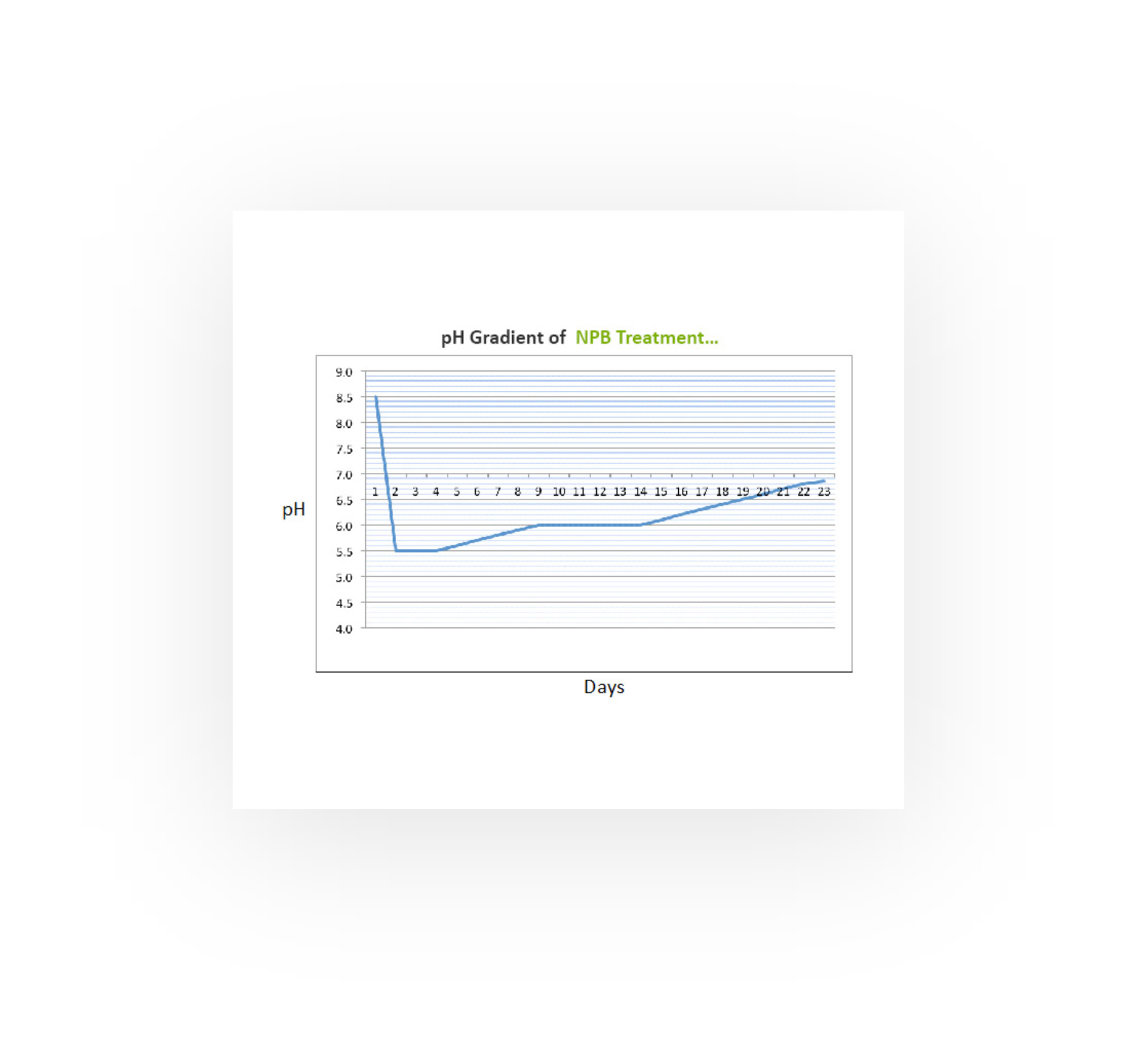

- pH of mass comes down from 8.0-9.0 to 5.5-6.0 in 24 hours time, which kills harmful microbe & prevents loss of Nitrogen in the form of ammonia

- Composting time is less than 4 weeks, hence, no loss of carbon in the form of CO, CO2 or CH4

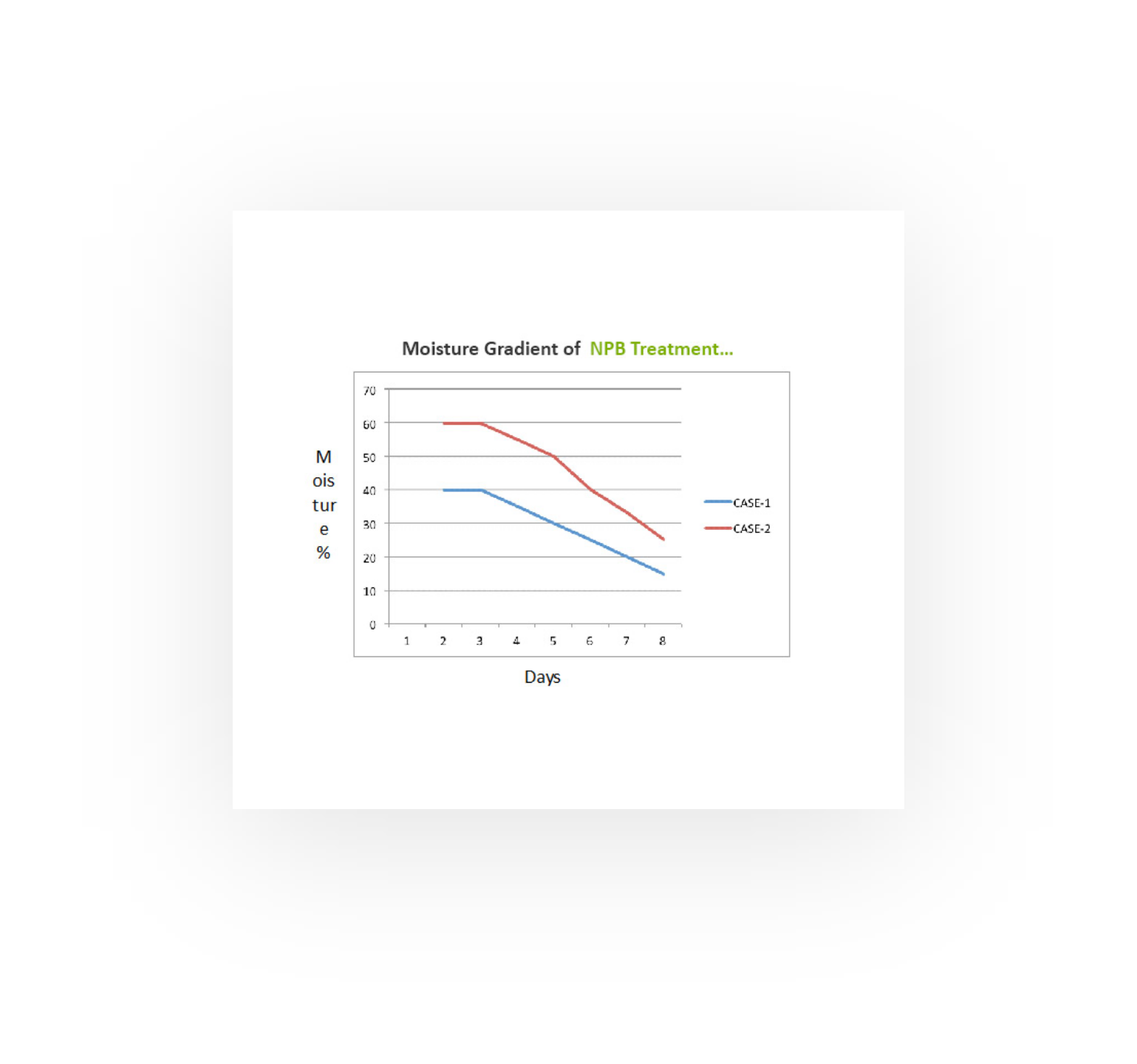

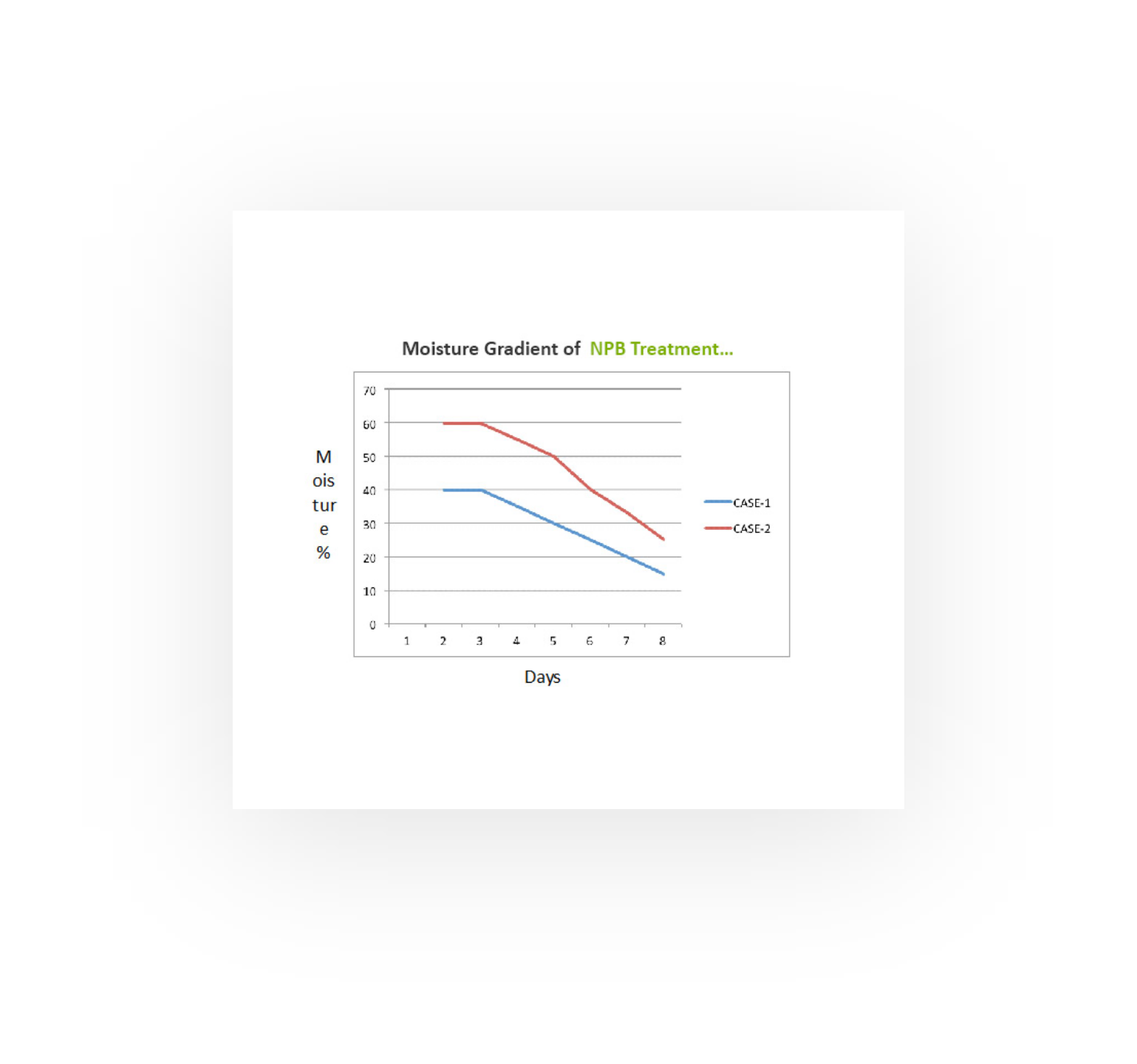

- As the temperature goes more than 80° C, No leachate generation, hence no additional cost for leachate management & treatment.

- Our process can efficiently produce Refused Derived Fuel (RDF) in form of Briquettes / Pellets, which is further used for steam & power generation. RDF has calorific value of 2500-3300 kcal/kg, so, IEC RDF is an economically viable solid fuel.

- Sale of RDF on regular basis will generate cash flow for the project & at the same time will reduce the requirement of working capital. RDF can be used in gasifiers or steam boilers to generate POWER making complete project more economically viable.